Does Your Sourcing Solution Align with Your Procurement KPI Strategy? 4 Critical Areas to Examine & Align

Key Takeaways

- CPOs are concerned about competitiveness, meeting demands and stakeholder requirements, standardizing procurement processes, and other factors, including digitization, advanced analytics, material shortages, and supply chain regulations

- They need to align essential areas of their procurement KPI strategy with the organization’s overall business objectives to achieve their goals and mitigate issues

The Full Article

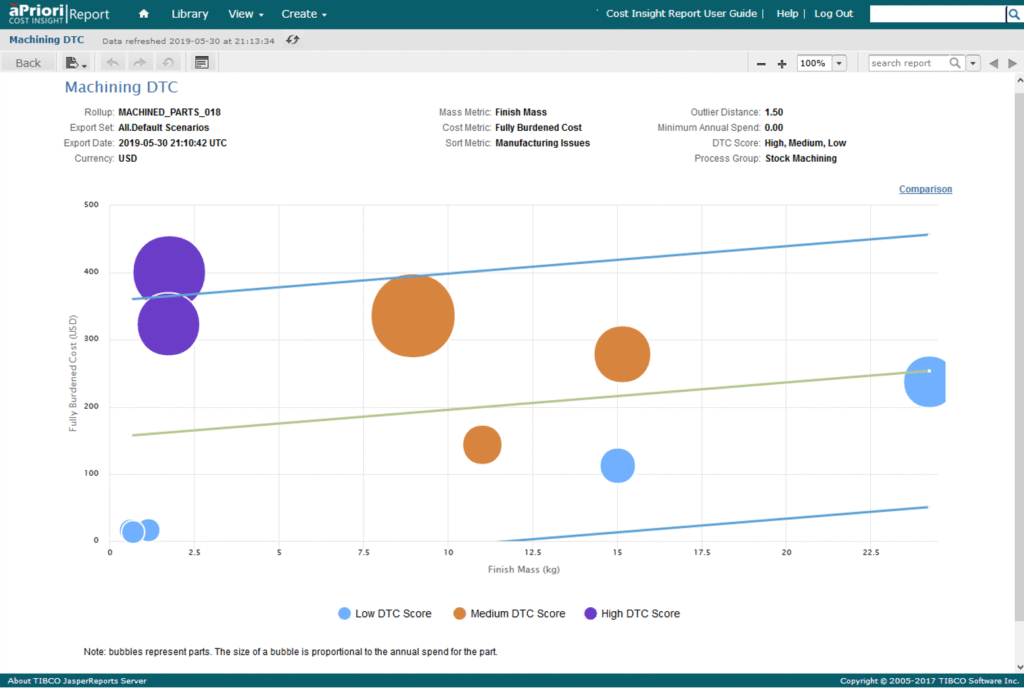

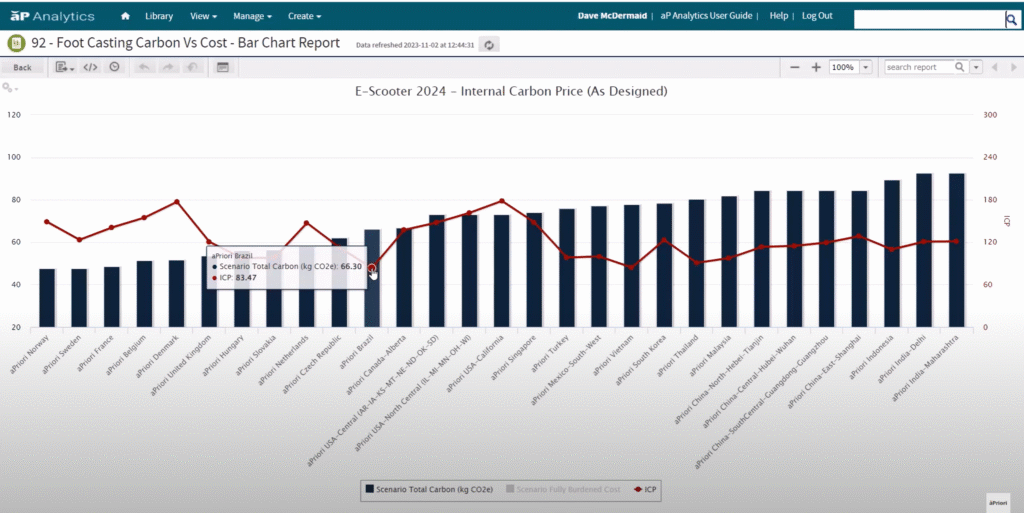

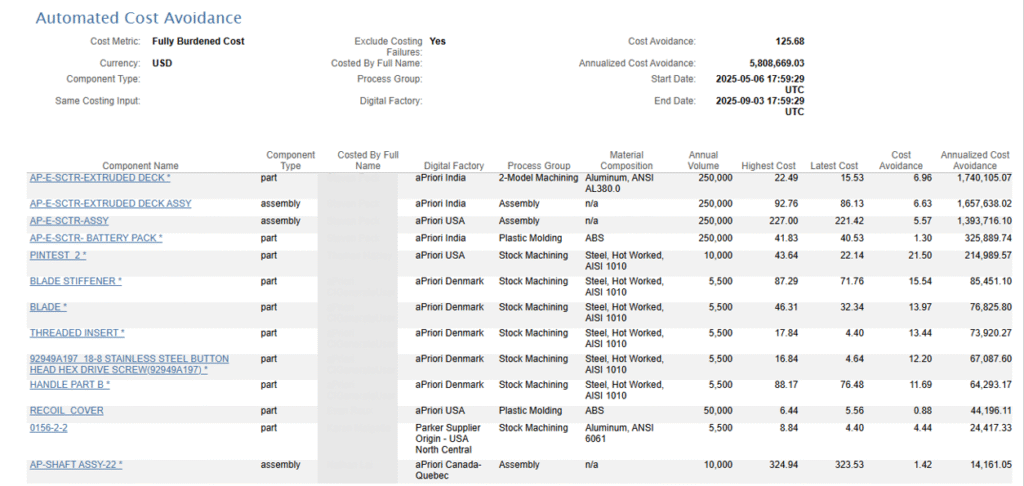

Today procurement is more than just cutting costs; it’s a strategic function that drives value not only within the procurement function but can be leveraged throughout a manufacturing organization. To truly succeed, procurement teams must align their efforts with business objectives and also establish key performance indicators (KPIs) that reflect their contributions. It is crucial to highlight the positive impact that a procurement KPI strategy can have on a business. Why? It paves the way for allocating funds for efficiency-improving technologies, training, and resource investments, and potentially even incentivizing bonuses. What’s more, procurement can better prepare its fiscal planning and perform check-ins at regular intervals to identify areas for improvement. These capabilities further foster a more proactive approach, building in faster response times and more agility in the face of disruptions rather than just trying to withstand it. The result is a strategic plan that helps the organization become more “anti-fragile”. The same Kearney study reveals that the priorities of Chief Procurement Officers (CPOs) mirror new challenges and a changing landscape. CPOs major procurement concerns regarding competitiveness include talent and resource constraints (46%), integrating procurement throughout the organization to meet business demands and understand stakeholders requirements (41%), standardizing procurement processes (27%), digitization and advanced analytics (25%), and external factors such as materials shortage and regulations (25%). This is where aPriori Technologies can be a game-changer. Let’s explore how aPriori directly addresses common procurement challenges and boosts these critical KPIs. Procurement Value Contribution: Procurement’s value beyond cost savings (Cost Savings + Innovation Contributions + Risk Mitigation Value)/Total Spend Procurement’s value extends far beyond simple cost savings. It includes removing process inefficiencies and mitigating risk. aPriori’s digital manufacturing platform provides a real-time understanding of product costs and manufacturability early in the design phase. By simulating production, it helps streamline product development, identify opportunities for design optimization and material substitution, which can significantly lower costs without sacrificing quality. This proactive approach helps procurement performance as teams are able to contribute to innovation by influencing product design. aPriori also mitigates risks by flagging designs that are difficult or expensive to manufacture, preventing potential supply chain disruptions and bottlenecks, and unexpected cost overruns. This holistic view of value directly contributes to a higher Value Contribution ratio. 2. Spend Under Management Spend Under Management: % of spend managed by procurement (Spend Managed by Procurement/Total Organizational Spend) x 100 A top procurement metric is to bring more spend under its direct control. However, capturing and analyzing procurement data from various sources can be a daunting task. aPriori provides a unified platform for understanding the cost drivers of products and parts. It helps procurement teams identify unmanaged spend by providing a comprehensive cost breakdown of the should cost for all manufactured parts, regardless of whether they are purchased from a supplier or made in-house. This visibility allows procurement to strategically engage with stakeholders and bring more spend under their management, thus increasing the Spend Under Management percentage. 3. Savings Forecast Accuracy Procurement Savings Forecast Accuracy: Accuracy of savings forecast (Forecasted Savings-Actual Savings)/ Forecasted Savings x 100 Forecasting savings can be a tricky business. Inaccurate forecasts can lead to budget shortfalls and a loss of credibility for the procurement department. aPriori helps address this by providing accurate, data-driven cost models that enable procurement professionals to model different scenarios—such as changing materials or manufacturing locations—and precisely calculate the impact on procurement costs. This data-driven approach dramatically improves the accuracy of savings forecasts, leading to a lower variance between forecasted and actual savings and improving the Procurement Savings Forecast Accuracy metric. 4. Cost Avoidance Cost Avoidance: Money saved by avoiding extra costs (Avoided Costs/ Total Spend) x 100 Cost avoidance is about proactively preventing future expenses. This is where aPriori’s technology truly shines. By integrating with CAD systems, aPriori can analyze product designs and identify potential cost drivers before a quote is even requested. For example, it can flag a design that requires an expensive, specialized machining process or tooling operation and help identify a more cost-effective alternative. This proactive intervention helps procurement teams avoid unnecessary costs from the get-go, directly contributing to a higher Cost Avoidance metric. Today’s procurement teams need every competitive advantage. By objectively analyzing their supply chains and supplier relationships as well as supplier performance across the organization, not just in the procurement process, they can unlock a strategic and competitive advantage. aPriori empowers procurement teams to move beyond traditional cost reduction, clarify procurement successes and obstacles, realign objectives where necessary, improve decision-making, and become strategic value drivers. Through automation and unparalleled visibility into product costs and manufacturability, aPriori helps organizations improve key procurement KPI measures, ultimately strengthening the procurement function and its impact on the bottom line, including procurement ROI.Optimizing Essential Procurement KPIs with aPriori

Procurement’s Strategic Value Driver Partner

Data is Sourcing’s New Currency

Harness data-driven insights for greater transparency, better decision-making, faster time to market, and increased agility and profitability