Case Study

DFM Delivers Value Right Now! Ask Dana. They Saved Millions with DFM/DTC in Year 1

Introduction

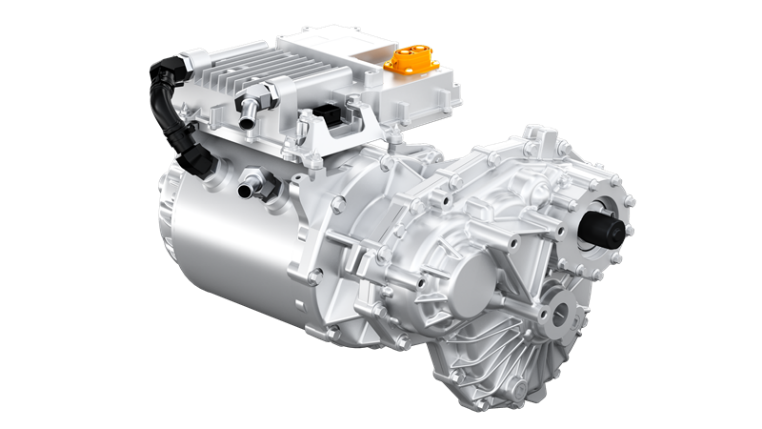

Dana’s adoption of aPriori’s Manufacturing Insights Platform has been transformative, enabling significant cost savings, improved design processes, and enhanced supplier negotiations. By embedding cost, carbon and DFM (Design for Manufacturability) visibility into product development, the organization continues to drive profitability and maintain a competitive edge in the evolving automotive landscape.

Watch Scott Steward, Sr Engineering Manager, deliver this presentation at the recent Manufacturing Insights Conference in Detroit

Company Details

Industry

Automotive

Number of Employees

42,000

Revenue

$10.6 billion

Website

aPriori Product

aP Design

The Problem

Dana Corporation, a leading global automotive supplier, were facing increasing pressure to reduce production costs while maintaining quality and competitiveness, especially in the rapidly evolving electric vehicle (EV) market. Persistent challenges included late-stage design changes, cost overruns, and inefficiencies in supplier negotiations.The Solution

In the 2 years since implementing aP Design as the design-to-cost solution, cost analysis is now fully integrated as a key factor in product design and development. This approach enabled them to evaluate designs for manufacturability and cost efficiency early in the process, minimizing the need for costly iterations.Results

- Cost Reduction Across Existing Products: Within two years, the company identified cost-saving opportunities amounting to 8% of total spend, realizing 4% in the first year.

- New Product Optimization: aPriori enabled triple the design efficiency for new products by reducing redesigns and improving manufacturability assessments.

- Global Rollout Strategy: Aiming for 75% adoption in new product developments, the company expects this standardized approach to yield consistent operational and cost benefits.

- Supplier Negotiation Improvements: aPriori’s detailed cost breakdowns empowered purchasing specialists to negotiate cost components more effectively, achieving significant savings on high-volume components.

Case in Practice

- Iterative Design Savings: One design engineer used the tool to consolidate components, eliminating redundancies and simplifying parts. This resulted in a 5% cost reduction on a key program, delivering millions in savings.

- Enhanced Supplier Engagement: The purchasing team leveraged cost insights to negotiate with suppliers, achieving over $2 million in annual savings on a single component by identifying inflated costs.

Future Plans

With proven success in reducing costs and improving product competitiveness, Dana plans to expand the tool’s use to other business units. The goal is to position Dana as a preferred supplier in the electrification market by aligning global operations under a unified design-to-cost strategy. To achieve this goal, they want to be the most responsive, cost-efficient supplier to Automotive OEMs.

Experience aPriori in Action

Meet with an aPriori expert and learn how we can help you eliminate product costs, improve productivity, and reduce your carbon footprint.