Case Study

How Rivian Drives Cost Efficiency in EV Production with aPriori

Introduction

Rivian, a leader in electric adventure vehicles, is redefining performance and sustainability in the EV market. But beyond bold design and breakthrough engineering, Rivian’s success increasingly depends on achieving cost efficiency at scale.

To address rising BOM costs across complex vehicle platforms, Rivian’s Cost Engineering team adopted aPriori’s aP Pro platform. With it, the team has built a modern should-costing process, identified cost drivers early in the design phase, and supported fact-based supplier negotiations—resulting in measurable material cost savings across both existing and next-generation programs like R1 and R2. In parallel, the team is also piloting aP Generate and deployment to production is now in progress.

Company Details

Industry

Automotive/Electric Vehicles

Number of Employees

14,861

Revenue

$3.4 billion

Website

aPriori Product

aP Pro

The Problem

Time-consuming cost estimation processes, dependent on supplier quotes.The Solution

Continuous loop of cost insights throughout the vehicle lifecycle, from new part introduction to sourcing and change management.About Rivian

Founded in 2009 and headquartered in Irvine, California, Rivian Automotive is dedicated to designing, developing, and manufacturing electric vehicles that are built for adventure. Its lineup includes the R1T (pickup), R1S (SUV), and a growing range of electric Rivian Commercial Vans. Production is based in Normal, Illinois.

With the upcoming R2 and R3 platforms, Rivian is entering its next phase—delivering the Rivian experience at more accessible price points. To do this profitably, the company is focusing heavily on structural simplification, supply chain optimization, and BOM cost control.

The Challenge - BOM Cost Pressure and Scale:

As Rivian expanded across vehicle programs, the Cost Engineering team faced growing challenges:

- Complex, high-precision parts required for off-road durability and premium quality

- Time-consuming cost estimation processes, dependent on supplier quotes

- Uncertainty predicting costs during initial design

Rivian needed a solution that could enable scalable, real-time cost visibility across platforms and support data-driven decisions during both design and sourcing.

The Approach Prior to aPriori:

Before implementing aPriori, Rivian did not have a standardized starting point for cost calculations, which made it difficult to compare costs across projects. Inconsistent results made it difficult to compare costs or validate assumptions across projects.

Even where templates existed for common processes like sheet metal or plastics, it was difficult to represent the full range of manufacturing methods needed to produce a car – where several parts may involve castings, extrusions, machining, and more. Building on their existing capabilities, teams sought to streamline the estimation of these complex processes, aiming to reduce turnaround times and drive greater precision in supplier quote comparisons.

With aPriori, Rivian gained a single, data-driven platform that standardizes cost estimation across all process groups.

The Solution - aP Pro for Real-Time Cost Intelligence:

Rivian implemented aPriori’s aP Pro platform as a core cost engineering tool. The team uses it to:

- Drive should-costing from 3D CAD: Using aP Pro’s digital factories, Rivian rapidly generates accurate, repeatable cost estimates based on part geometry, materials, tolerances, and manufacturing locations—setting objective internal cost targets.

- Identify cost drivers during design: Engineers use aP Pro to analyze which features or manufacturing processes are driving costs. These insights guide more cost-efficient design decisions.

- Strengthen supplier negotiations: With real-time manufacturing data like regional labor rates, material costs, and machine cycle time and utilization Rivian’s procurement and cost teams engage suppliers with confidence—challenging overquoted items and unlocking more strategic pricing.

- Enable ongoing cost optimization: aP Pro supports a continuous loop of cost insights throughout the vehicle lifecycle, from new part introduction to sourcing and change management.

Results

Material Cost Savings

“As we grow and work on future products for mass market adoption, it is important we evaluate all supplier costs in detail to reduce our BOM costs to be competitive in the market.”

— Rizwan Mohammed, Senior Manager, Cost Engineering

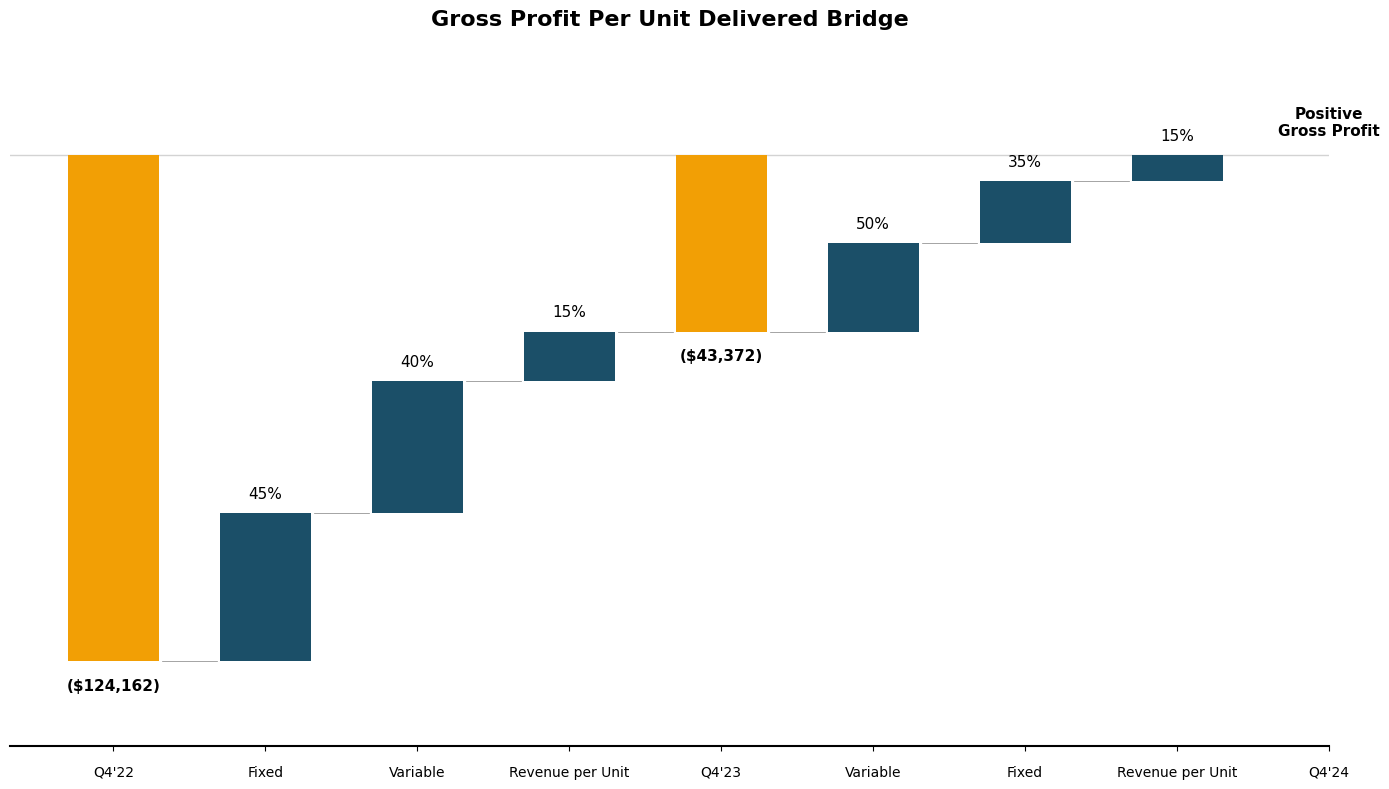

Breakdown of Q4 2023 gross profit improvement per vehicle (~$81,000) compared to Q4 2022

This chart illustrates how Rivian improved gross profit per vehicle by approximately $81,000 in Q4 2023 compared to the same period in 2022. Notably, 40% of this improvement came from variable cost reductions, primarily driven by material cost savings. These significant cost reductions were successfully executed through a collaborative, cross-functional effort involving Rivian’s Cost Engineering team. Their strategic initiatives included comprehensive early cost analysis, manufacturing process simulation, and data-driven supplier negotiations. aPriori’s aP Pro platform served as a valuable data and simulation resource, enabling the team to execute their initiatives effectively and contribute to the achievement of the material cost savings.

Expected R2 BOM Cost Savings

“As communicated previously by Rivian, BOM cost for R2 is significantly lower than R1 platform. This was achieved by dedication of all teams at Rivian including Engineering, Operations, Cost Engineering, Finance, etc.

One important aspect of this was Cost Engineering developing timely, consistent, and detailed Should Cost for data driven negotiations with the suppliers. Without aPriori, it would be difficult to do so much work on time with consistent level of output”.

— Rizwan Mohammed, Senior Manager, Cost Engineering

Looking Ahead

Rivian’s vision is to create a fully connected, intelligent product development process—one where cost, design, and manufacturability insights flow seamlessly from concept to production. By embedding cost intelligence directly into the design workflow, they’ll enable engineers to make informed decisions earlier addressing the 80% of cost determined in the initial design phase and driving products to market faster and more efficiently.

Conclusion

Rivian effectively uses aPriori to drive should-costing, enhance supplier negotiations, and reduce overall BOM costs. By leveraging the software’s detailed manufacturing cost analysis, Rivian is optimizing its supply chain, improving vehicle profitability, and maintaining a competitive edge in the electric vehicle market.

Experience aPriori in Action

Meet with an aPriori expert and learn how we can help you eliminate product costs, improve productivity, and reduce your carbon footprint.