Stretch Form Machine Selection

For the transverse stretch forming routing, the cost model selects the lowest-overhead, feasible machine that has transverse pull capability (see Machine Feasibility for Stretch Forming).

For the longitudinal stretch forming routing, the cost model selects the lowest-overhead, feasible machine that has longitudinal pull capability (see Machine Feasibility for Stretch Forming).

Overhead is the sum of the machine properties Direct Overhead Rate and Indirect Overhead Rate.

Note that aPriori selects only from preferred machines, if there is a feasible preferred machine and the cost model variable usePreferredMachines is set to true (the default in starting point VPEs). If there is no feasible preferred machine, or if the cost model variable usePreferredMachines is set to false, aPriori selects from all machines. A machine is preferred if the machine property isPreferred (typically displayed as Is Preferred) is true.

See the following sections for more information:

Machine Feasibility for Stretch Forming

A machine has transverse pull capability if the machine property Transverse Pull Capability is true. Such a machine is feasible if it can accommodate the dimensions of the blank and can provide the required pull force; that is, a transverse machine is feasible if all the following hold:

• Required pull force: the pull force required for the part does not exceed the machine’s pull force capability (specified by the machine property Press Force). The required pull force, for a part and a given material, is proportional to the area of the Xsection orthogonal to the pull direction. See Required Pull Force for Stretch Forming for more information.

• Required length: transverse Xsection GCD property Curve Length Extended Aligned is less than the machine property Max Jaw Distance.

• Required jaw width: transverse Xsection GCD property Curve Length Extended Orthogonal is less than the machine property Jaw Length.

A machine has longitudinal pull capability if the machine property Longitudinal Pull Capability is true. Such a machine is feasible if it can accommodate the dimensions of the blank, provide the required pull force, and accommodate the curvature of the part; that is, a longitudinal machine is feasible if all the following hold:

• Required pull force: the pull force required for the part does not exceed the machine’s pull force capability (specified by the machine property Press Force). The required pull force, for a part and a given material, is proportional to the area of the Xsection orthogonal to the pull direction. See Required Pull Force for Stretch Forming for more information.

• Required length: longitudinal Xsection GCD property Curve Length Extended Aligned is less than the machine property Max Jaw Distance.

• Required jaw width: longitudinal Xsection GCD property Curve Length Extended Orthogonal is less than the machine property Jaw Length.

• Required curvature: part length-to-height aspect ratio in the transverse direction must not be less than the machine’s minimum achievable length-to-height aspect ratio for a jaw set (the set of jaws gripping along one side of the blank).

The part aspect ratio in the transverse direction is the length of the transverse Xsection divided by its height:

o The length is the difference between the y components of the Xsection properties Rectnagle Lower Left and Rectangle Upper Right.

o The height is determined as described in Xsection Curve Height for Stretch Forming.

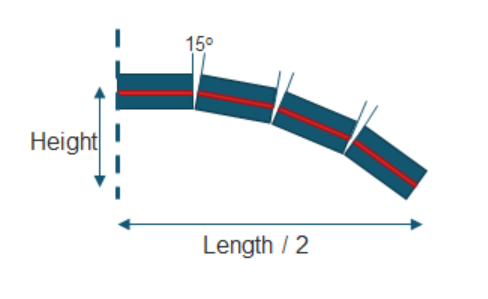

The minimum jaw set aspect ratio depnds on the following:

o Individual gripper length (specified by the cost model variable gripperIndividualLength--304.8mm in starting point VPEs)

o Maximum angle by which a gripper’s orientation can differ from an adjacent gripper’s orientation (specified by the cost model variable gripperMaxRotationAngle--15 degrees in starting point VPEs)

o Maximum jaw set length, specified by the machine property Jaw Length. (The number of grippers is estimated as this value divided by individual gripper length.)

Required Pull Force for Stretch Forming

The pull force required for stretching is given by the following formulas:

Required Transverse Pull Force = Flow Stress * Longitudinal Cross Sectional Area

Required pull force for transverse stretching is the product of the following:

• Flow stress (see formula)

• Longitudinal cross-sectional area: this is the area of the longitudinal Xsection (see formula)

Required Longitudinal Pull Force = Flow Stress * Transverse Cross Sectional Area

Required pull force is the product of the following:

• Flow stress (see formula)

• Transverse cross-sectional area: this is the area of the transverse Xsection (see formula)

Flow Stress = (Solution Treated Tensile Yield Strength +

Solution Treated Ultimate Tensile Strength) / 2

Flow stress depends on the following material properties:

• Solution treated tensile yield strength: specified by the material property Annealed Tensile Yield Strength.

• Solution treated ultimate tensile strength: specified by the material property Annealed Ultimate Tensile Strength.

Longitudinal Cross Sectional Area = Longitudinal Length * Stock Thickness

This is the area of the longitudinal Xsection. Longitudinal cross-sectional area is the product of the following:

• Longitudinal length: specified by the Curve Length Extended Aligned property of the longitudinal Xsection.

• Stock thickness (thickness of the selected stock--see Material Stock Selection for Stretch Forming)

Transverse Cross Sectional Area = Transverse Length * Stock Thickness

This is the area of the transverse Xsection. Transverse cross-sectional area is the product of the following:

• Transverse length: specified by the Curve Length Extended Aligned property of the transverse Xsection.

• Stock thickness (thickness of the selected stock--see Material Stock Selection for Stretch Forming)