How Soucy Streamlined Their Quoting Process with International Suppliers

Simply waiting for an initial quote from suppliers can introduce a substantial delay to the product development process–particularly when suppliers are on the other side of the planet.

In this case study, we explore how Canadian-based manufacturer Soucy uses aPriori to accelerate quoting and deepen collaboration with its Chinese suppliers, all while achieving faster time-to-market and quicker RFQ responses than ever.

Company Details

Industry

Industrial Machinery & Equipment

Number of Employees

1,700

Revenue

$677 Million

aPriori Product

aP Pro

The Problem

Reduce Delays in the Quoting Process to Accelerate Time to MarketThe Solution

Use Digital Factories to Cost Faster and Iterate MoreWho is Soucy?

Soucy is a Canadian-based manufacturer which designs and manufactures various components for leading makers of motorsport, industrial, agricultural, and defense vehicles.

With over 1,700 employees working across 12 facilities in North America and Asia, Soucy has a 50+ year history of creating solutions for everything from snowmobiles to tank tracks.

Problem: Reduce Delays in the Quoting Process to Accelerate Time to Market

The power sports industry is defined by continuous product iteration and short terms of ownership (about three years on average). In this context, rapid product development cycles are critical to keeping up with fast-moving customer tastes.

Soucy’s Power Sports Division designs products that are manufactured in China, and working with suppliers from the other side of the world often introduced delays. After designing a product and receiving internal approval, Soucy’s engineers would send specifications to their China division for a price. This process could take up to seven days just to receive an initial cost estimate, leading to overall lead times of 9-10 days to respond to a customer quote.

Worst of all, if a cost or manufacturability issue was only uncovered after this quote phase, the entire cycle would need to be repeated, complete with another week-long wait for suppliers’ feedback on the updated design.

Soucy also operates a print-to-build business, which manufactures components based on customers’ unique designs. The delays associated with quoting also slowed down the pricing process for this offering, delays which risked losing business to the competition. The right solution would need to dramatically speed up the quoting process while allowing Soucy’s design engineers to stay agile and achieve a faster time-to-market.

Solution: Use Digital Factories to Cost Faster and Iterate More

aPriori emerged as a strong fit for Soucy’s three key criteria for an enhanced cost modeling tool:

After hearing glowing reviews from several of their own customers, Soucy decided to move forward with aPriori for the approximately 350 products they design annually.

By simulating manufacturing in a digital factory using aPriori, Soucy’s design engineers can generate a robust cost model while a design is in its initial design stages. aPriori’s digital factories are configured to reflect the specific manufacturing capabilities and cost structure of Soucy’s suppliers, allowing designers to move forward with confidence that a simulated cost model will accurately reflect the final quote. Design-stage manufacturing simulation also helps catch cost and manufacturability issues early, when there is still time to consider more efficient design alternatives.

Result: A Streamlined Quoting Process Ready for Dynamic Customer Requirements

Soucy has used aPriori to eliminate the need for supplier quotes when creating an initial cost estimate, successfully reducing their cost visibility lead time to just 2.5 days, with an average accuracy of +/-3% of the final supplier quote. This dramatically shortened timeline for quoting enables faster time to market. Now, customers know who to call when they need a quote fast.

An accelerated quoting process also gives design engineers more time to iterate and identify opportunities for further value engineering. Soucy can even pass along simulation-driven recommendations for savings to its customers, enhancing its own value-added as a supplier.

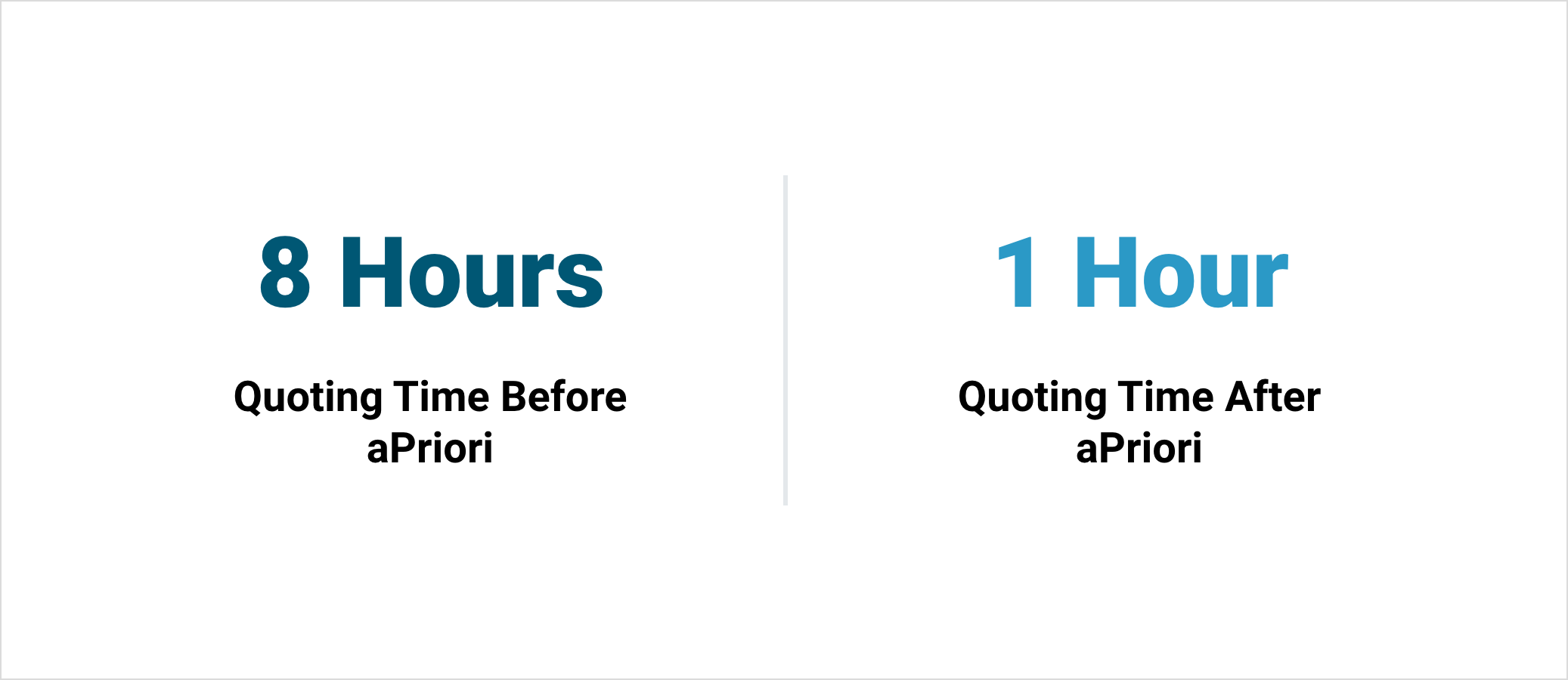

By speeding up the quoting process, aPriori also reduces the internal resources needed to keep up with new RFQs.

Based on these successful results, Soucy plans to expand its aPriori implementation to more of the company’s business units. Their tractor division has already begun to report some impressive initial successes.

At our recent Manufacturing Insights Conference, Soucy’s Caroline LeClerc discussed how she uses aPriori to run cost analysis globally for key regions like China, Vietnam, and the United States to determine which regions and processes will offer the most value. She shared how initial work using aPriori for cost analysis has expanded into collaborative supplier negotiations. And moving forward, Soucy plans to leverage aPriori’s sustainability features to improve carbon transparency for their supply chain. Listen in on this short video interview with Caroline below.

Experience aPriori in Action

Meet with an aPriori expert and learn how we can help you to eliminate product costs, improve productivity, and reduce your carbon footprint.