Do you have the right technology to reduce costs and improve supplier negotiations?

aPriori provides fact based data for effective supplier collaboration and negotiation

Has productivity slowed to a crawl?

Accelerate time to market and innovate faster and better with aPriori

Do you consistently experience material waste in the product development lifecycle?

Incorporate real-time sustainability insights into design and production with aPriori

aPriori Manufacturing Insights Platform

The leading cloud-based platform used by manufacturers to unlock cost, manufacturability, and carbon insights for increased product profitability and sustainability.Watch the Video

We have customers in the high tech, aerospace & defense, automotive, and industrial equipment industries.

TE Connectivity: Captures Savings

TE Connectivity uses aPriori cost analysis to improve bottom-line outcomes.

Nikola: Found Top Cost Drivers

With aPriori, Nikola identified its top-10 cost drivers in injection molding.

Carrier: $21M in Value

Carrier used manufacturing simulation to shave cost from components.

Alstom: 40% Savings On Supplier Costs

Alstom reduced supply chain quotes to zero using aPriori digital factories.

Signify: Digitize Procurement Process

Signify automated should cost analysis to drive savings.

Harman: Supplier Cost Transparency

Harman got to true cost transparency in supplier negotiations.

Spirit AeroSystems: RFQs + DFM

Spirit sped up RFQs while providing value-added DFM insights.

axcelis: Value Engineering

Product costing software streamlined value engineering for axcelis.

85

%

of investors considered environmental factors in their investments

54

%

of the world’s energy consumption is from manufacturing

80

%

of a product’s early design determines its environmental impact

81

%

of executives say sustainable sourcing is extremely important to their businesses

Trending in aPriori Resources

6 Ways EU Automakers Can Outmaneuver Competitors in the Race Toward Net Zero

Key Takeaways:

EU automakers face stringent environmental regulations, driving a need for immediate climate action to reduce greenhouse gas emissions (GHG emissions) a

Design for Manufacturing Examples: Real-Life Engineering Case Studies

Key Takeaways:

More than 70% of a part’s cost can be locked in during the early design phase

Adopt a robust DFM process using d

Navigate the High Cost of Sourcing Materials to Boost Profitability

Key Takeaways:

With market-driven cost and manufacturing data, sourcing teams can avoid costly missteps and delays in material procurement

A digital manufactu

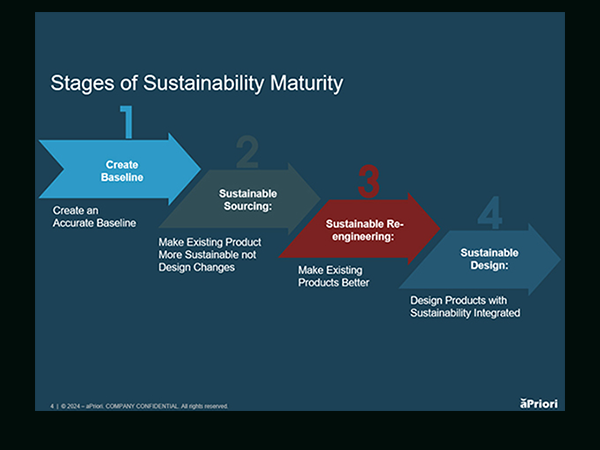

4 Steps to Optimizing Sustainable Design and Manufacturing

Key Takeaways:

aPriori's four-phase sustainability maturity model integrates sustainable practices into manufacturing while balancing profitability and environmental i

Manufacturing Challenges? Try Our Online First Aid Tool

Key Takeaways:

If you don’t know the cause of your manufacturing challenge, it’s hard to get the right prescription to meet your goals. The right manufacturing cha

5 Ways Manufacturers can Fix Strategic Sourcing & Drive Value

Key Takeaways:

Fragmented and manual procurement operations limit the ability to use supplier relations as a competitive advantage.

Strategic sourcing drives